|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

289.

Time to fit the new roof.

|

290.

The new roof ali is deliver on a roll.

|

291.

Ali roof ali lifted onto the Cheetah roof. |

|

|

|

|

|

|

|

|

|

|

|

|

292.

Preparing to unroll the coil |

293.

This is a minimum of a 2 person job. |

294.

Positioning of the roof ali. Enough is needed on both sides of the van to allow

a 5mm overlap. |

|

|

|

|

|

|

|

|

|

|

|

|

295.

Rear end of the van. |

296.

Excess ali at the bottom rear end. |

297.

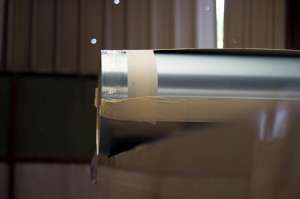

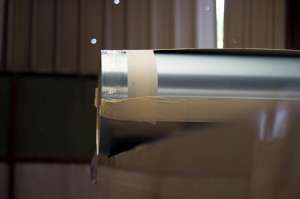

Overlap at the front. |

|

|

|

|

|

|

|

|

|

|

|

|

298.

Inside the overhead cab! |

299.

Marv seals to underside of the ali

roof using Sika 710. |

300. Sika is used along the entire

length front to rear. |

|

|

|

|

|

|

|

|

|

|

|

|

|

301.

Plenty of overlap this side too.

|

302.

Fiddling with the kitchen slant.

|

303.

A steady hand is needed when it comes to trimming the ali. |

|

|

|

|

|

|

|

|

|

|

|

|

304.

Clare uses something to keep the ali as flat as possible at the rear while Marv

staples to ali. |

305.

Any staples that are proud are knocked in. |

306.

Nearly there. Fitting the front window holds the ali flat.

|

|

|

|

|

|

|

|

|

|

|

|

|

307.

Starting to cut out the back window opening. |

308.

3/4 of the way. |

309.

Done. |

|

|

|

|

|

|

|

|

|

|

|

|

310.

The back window is fitted. |

311.

The front edge is trimmed to

length and the ali trim screwed on. |

312.

No doubt it was a long day,

but it's there. |

|

|

|

|